Woodsmith Shop Season 2

The Woodsmith Shop is designed to help you get the most out of your woodworking shop with helpful tips and techniques. Whether viewers are just starting out or have been woodworking for years, they'll find something new in every episode.

Watch NowWith 30 Day Free Trial!

Woodsmith Shop

2007 / TV-G

The Woodsmith Shop is designed to help you get the most out of your woodworking shop with helpful tips and techniques. Whether viewers are just starting out or have been woodworking for years, they'll find something new in every episode.

Watch Trailer

With 30 Day Free Trial!

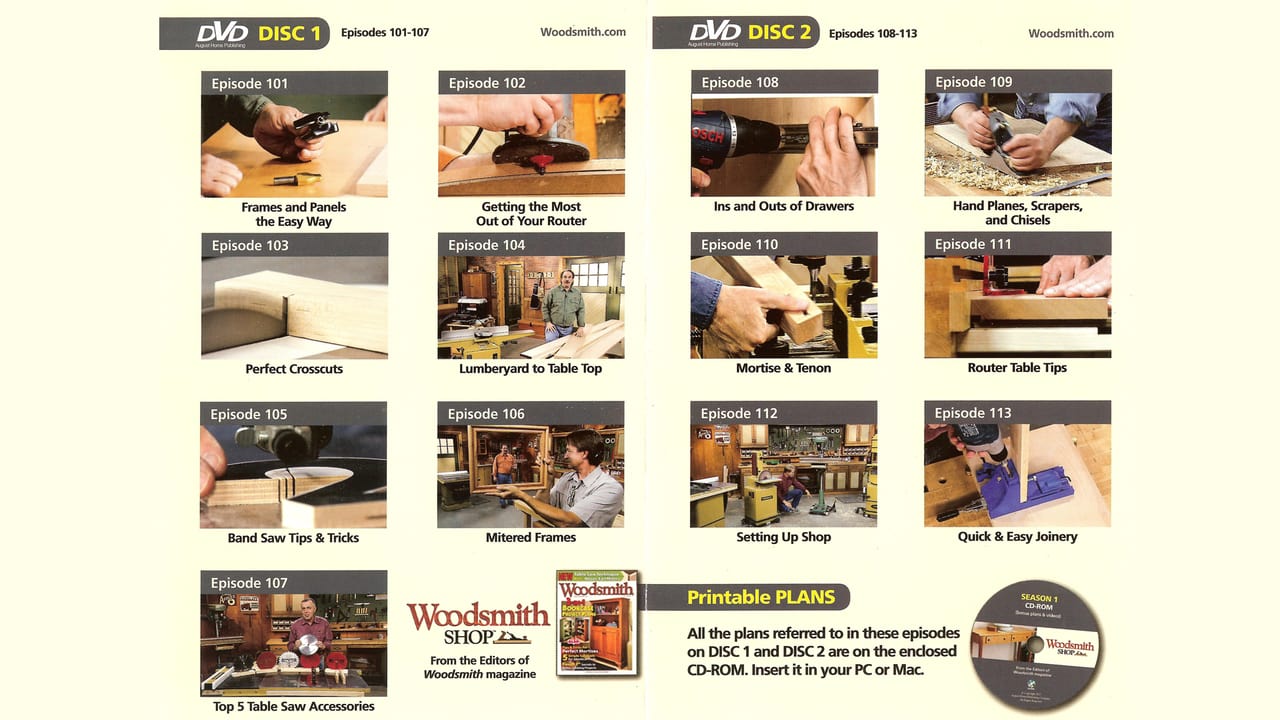

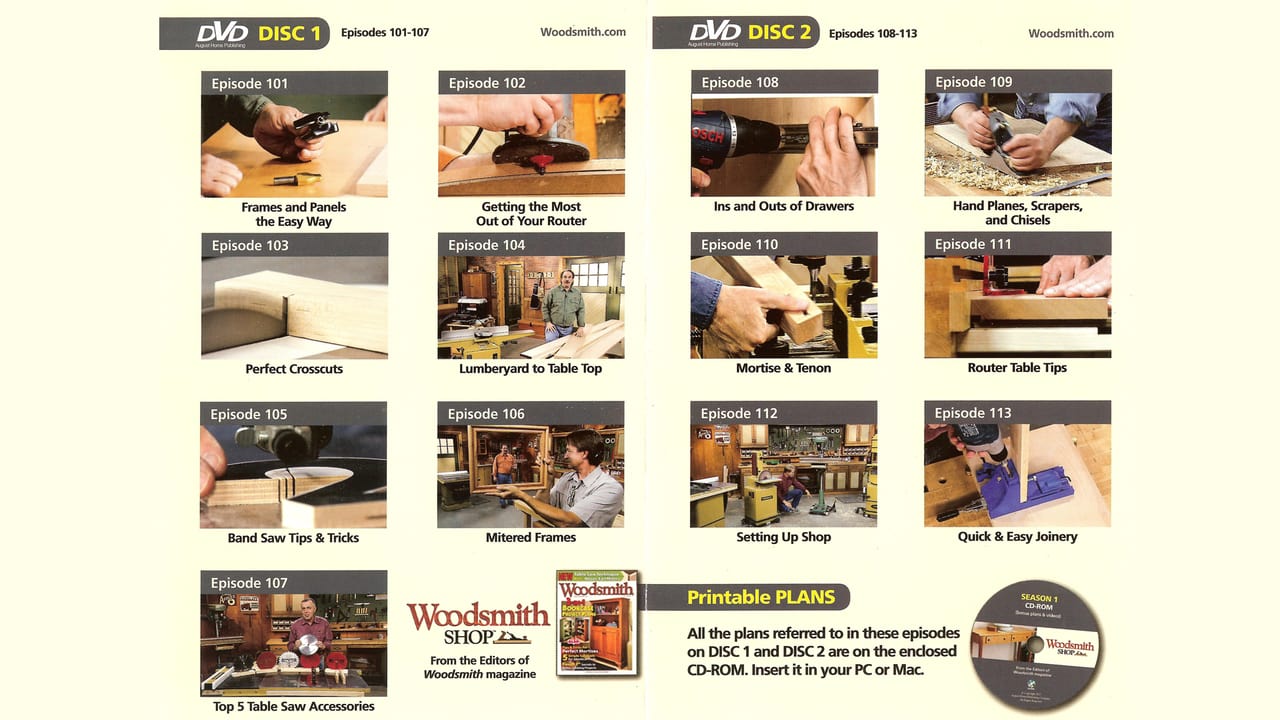

Woodsmith Shop Season 2 Full Episode Guide

Over the past 30 years, the editors have shown hundreds of shop tips in Woodsmith magazine. Now they share their top tips for getting the most out of your table saw, router table, drill press, and more.

The last 2 steps can be the most important part of a project: sanding and applying a finish. The editors look at the sanding tools and techniques to get the best results. Then they share their favorite, fast and fool-proof finishing methods.

The editors of Woodsmith choose three of our most popular shop storage projects that you can build in a weekend: a peg board storage system, a roll-around shop cart, and a lumber storage rack.

There's more to making a table leg than just cutting a long board. First, learn the secrets to getting a perfect grain pattern on a leg. Then the Woodsmith editors show a simple jig for cutting tapered legs, both two-sided and four-sided, and a special technique for make a flared tapered leg.

Cutting boards to the exact width you need is best done on a table saw. The Woodsmith editors talk about the right saw blade to use, and then show the jigs and techniques to get a perfect rip cut.

From one simple project, a cutting board, the editors of Woodsmith show seven master techniques you can learn to use on hundreds of projects. Start by ripping narrow strips, then glue up a panel, and sand it smooth. Then use templates cut curves and sand them perfectly smooth.

A router table is one of the most important tools in the shop. It all begins with accessories for the fence and adding a micro-adjuster. Then the editors show how to use three common router bits to make 17 profiles, and how to make tenon and groove joinery on the router table.

The centerpiece of every shop is a workbench. The editors of Woodsmithshow step-by-step how to build our most popular weekend workbench using common building materials. Then how to add a vises and bench dogs to make is even more useful.

At some point all the pieces you cut for a project have to be assembled. The Woodsmith editors show how to dry-fit a cabinet to check the fit of all the pieces, the types of glue to use, and the techniques we use to clamp a cabinet so it's square.

The Woodsmith editors discuss four basic joints used to assemble the corners of a cabinet, a simple rabbet joint, a dado joint used for the top and bottom, a very strong locking joint called a tongue and dado, and a modern technique pocket screw joinery.

Adding a simple piece of molding can make all the difference in the appearance of a project. The Woodsmith editors show how to make three moldings on a router table: a quarter round, a cove molding, and bead molding.

A shelf can be just a piece of plywood. But the Woodsmith editors show how to add the right edging, either veneer tape or solid-wood, you can enhance the look. Or, add a wider strip to balance the look while adding strength to support the weight of all the books.

Looking back over the past 30 years, the editors of Woodsmith answer the questions: If we were starting woodworking today, what three tools would we buy first? What accessories would you add? And what are your best tips for using the tools? And finally, what project inspired you the most?

Free Trial Channels

Seasons