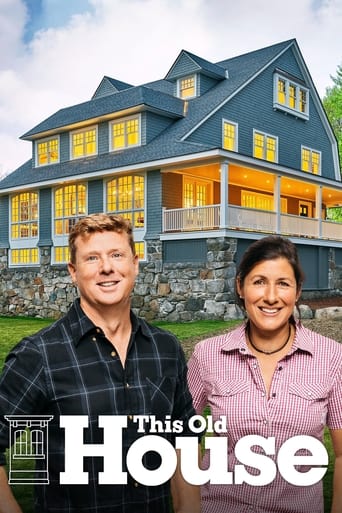

This Old House Season 30

TV's original home-improvement show, following one whole-house renovation over several episodes.

Watch NowWith 30 Day Free Trial!

This Old House

1979 / TV-G

Weston; New York City

Watch Trailer

With 30 Day Free Trial!

This Old House Season 30 Full Episode Guide

With the Brooklyn brownstone nearly complete, master carpenter Norm Abram and host Kevin O'Connor arrive to find a bustling sidewalk with both sod and furniture being delivered. In the backyard, landscape contractor Roger Cook sees how the sod is being laid down while local builder Michael Streaman installs the last of the missing spindles at the base of the main staircase. Norm visits Mount Laurel, New Jersey, to see how the turnings were made by both a CNC lathe and with chisels by hand. Design correspondent Carole Freehauf shows Kevin the finished rental apartment on the top floor. The apartment has a casual monochromatic scheme that lets the woodwork take center stage and a stunning kitchen with period-inspired details and modern amenities. Homeowner Karen Shen shows Norm the completed master bedroom level, now accessible from within the owner's unit by a vintage spiral staircase.

At the project house in Brooklyn, local builder Michael Streaman reinstalls the beautiful white oak entry doors that were absent for several months when they were stripped of old paint and restored by wood refinisher John Thomas. Inside, John works his way through the parlor woodwork, covering, blending and matching color as he goes. In the kitchen, local plumbing and heating contractors Randy and Erik Gitli finish their connections to the appliances, the kitchen sink and install a new pot filler over the range. On the second floor, homeowner Kevin Costello shows master carpenter Norm Abram the new temporary wall in the master bedroom that creates a nursery for their youngest son. Eventually, the wall can be removed when they take over the third floor apartment. At a landmark home store in the Flatiron district of Manhattan, design correspondent Carole Freehauf gives host Kevin O'Connor a lesson in shopping for furniture while making selections for the project house.

After a brief visit to the Brooklyn Navy Yard, master carpenter Norm Abram helps local builder Michael Streaman reinstall old interior door trim in the new library area. In Bensonhurst, host Kevin O'Connor finds countertop fabricator Alex DeMeo unloading a container of marble just in from Italy and the slabs of manmade quartz and resin being made into countertops. Later, the countertops are installed at the project house with cutouts for the range and seams made on site. In the basement, plumbing and heating expert Richard Trethewey meets electrical contractor Vinny Verderosa to see how the new service is set up for the three-family house. Then Richard meets local plumbing and heating contractor Randy Gitli to look at the mechanical room that contains two complete systems—one for the ground floor apartment and another for the top three floors. Upstairs in the master bath, tile contractor Mauro Zanutto shows Kevin his unconventional method for grouting the floor tile.

At the project house in Brooklyn, master carpenter Norm Abram learns how local wood refinisher John Thomas is using a faux painting technique to disguise old and damaged woodwork. The custom kitchen is installed in the owner's unit while design correspondent Carole Freehauf meets Ian Gibbs at his SoHo showroom to see window treatment options and how the shades are custom made in his Queens workroom. Tile contractor Mauro Zanutto arranges a mud bed for tile on the garden level floor while upstairs in the master bath he prepares to lay the mosaic floor by doing a complete dry layout. Also, in the garden level apartment, the finished countertops arrive for the kitchen.

At the project house in Brooklyn, host Kevin O'Connor arrives to find local builder Michael Streaman and stair fabricator Stephen Dijanic installing the vintage spiral stairs that the homeowners bought online. The new plaster medallion is installed in the parlor and design correspondent Carole Freehauf reveals the design choices for the two rental apartments. Homeowner Kevin Costello lays down click-together linoleum floor tiles in one unit while cabinet installer Oliver Earl deals with concealing ductwork over his cabinetry in the other unit. Finish carpenter Mario Quintuna shows master carpenter Norm Abram how he is rehabilitating the original five panel interior doors by patching holes, cleaning up edges and replacing panels. At the end of the day, the spiral stair is nearly complete and ready to be tested. Homeowner Karen Shen is thrilled with the way it looks and that Streaman found a way to modify it to make it fit.

At the project house in Brooklyn, homeowner Karen Shen shows master carpenter Norm Abram the progress in the owner's unit while flooring contractor Neale Rattray installs new white oak flooring in the top floor apartment. In the new master bathroom, local plumbing contractor Randy Gitli shows plumbing and heating contractor Richard Trethewey the showerhead combination that includes a master showerhead, a handheld showerhead and tub filler. The set up is equally complicated behind the walls with volume controls and a thermostatic valve that Randy installs that day. Design correspondent Carole Freehauf shows host Kevin O'Connor the paint color scheme for the first floor which will be monochromatic to let the beautiful woodwork take center stage. Local builder Michael Streaman takes Norm over to his woodworking shop in Greenpoint to see the progress on the custom kitchen and how his crew is replicating baseboard profiles using routers instead of expensive custom knives.

After starting the day at nearby Tom's Restaurant, host Kevin O'Connor finds homeowners Kevin Costello and Karen Shen inspecting the new exterior paint job at the project house in Brooklyn. Inside, general contractor Tom Silva finds local builder Michael Streaman laying down new 5/16" white oak flooring in the parlor with two accent strips of cherry as a decorative border. Nearby in Red Hook, plaster contractor Stuart Sobczynski shows Kevin how he's replicating the plaster crown mouldings for the house, and later, the new mouldings are installed at the house. In the back yard, landscape designer/contractor Bob Reitmeyer shows Kevin the progress on a new retaining wall, and the brick patio that is going down in a herringbone pattern with a soldier course border. On the garden level, local millwork contractor Mitch Berlin installs new replacement windows on the back of the house.

Host Kevin O'Connor and plumbing and heating expert Richard Trethewey visit lower New York Harbor, taking in the city skyline and the Statue of Liberty from the water, and from Liberty Island. At the project house in Brooklyn, master carpenter Norm Abram meets local wood refinisher John Thomas for an assessment of the multiple wood finishes in the house (including lots of deteriorating shellac) and how to properly restore them. At a tile showroom in Bensonhurst, designer Carole Freehauf shows homeowner Karen Shen some period-appropriate tile combinations for her bathrooms and kitchen. Back at the project house, Richard gets an update on the plumbing and heating progress, and sees how brothers Randy and Erik Gitli are converting the old steam radiators to hot water.

Host Kevin O'Connor and landscape contractor Roger Cook visit Prospect Park, a 585-acre urban oasis unofficially known as "Brooklyn's Backyard." At the project house, master carpenter Norm Abram meets contractor Michael R. Streaman and homeowner Karen Shen to see how the framing is progressing and to hear about their thoughts on the kitchen layout. To learn more about how brownstones were used in the past, architectural historian Charles Lockwood takes Kevin to Manhattan's East Village to see a perfectly preserved rowhouse dating to 1832, including the original intact kitchen in the basement. Then, to see how the old-fashioned spaces can be updated, they visit a restored brownstone in Park Slope, Brooklyn, to see how former kitchens were often converted into rental apartments, and how modern kitchens and baths can be either carved out or bumped out from existing spaces.

For the first time in the show's history, host Kevin O'Connor and master carpenter Norm Abram take This Old House on the road to New York City to restore a neglected 1904 brownstone in Brooklyn. Homeowners Karen Shen and Kevin Costello will convert the former rooming house into a three family home while preserving and restoring period detail wherever possible. In Brooklyn, Norm meets veteran brownstone remodeling contractor Michael R. Streaman at a similar job down the street to see how he transformed one of these rooming houses into a beautiful, modern family home. Back at the project house, Streaman gets to work on demolition and also starts stripping the paint off the back of the house to prepare the brick for re-pointing and eventually the installation of new energy-efficient windows.

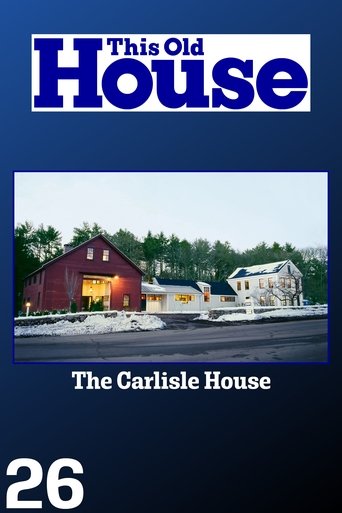

At the project house in Weston, landscape contractor Roger Cook tends to the last efforts on the landscaping front, which includes fresh sod, a bocce court, and a new irrigation system. Master carpenter Norm Abram and general contractor Tom Silva review how the choices of lighting, hardware and wood finishes contribute to the barn effect, and then they help Roger install the rustic granite hearthstone for the new fireplace. In the master bathroom, tile contractor Mark Ferrante lays the last of the handmade tile over the new cast concrete vanity sinks. Finishing touches are put on the security system and industrial light fixtures, and the signature "harvest table" (designed by architect Chris Adams) is delivered for dining room.

At the project house in Weston, landscape contractor Roger Cook installs a berm and fence in the front yard to screen out the busy street. Landscape architect Wes Wirth and homeowner Amy Favat review the native plants they've chosen for the new planting beds. Amy takes host Kevin O'Connor to a showroom and workshop in Florence, Massachusetts, where they both lend a hand in making the concrete countertops and sink. Back in Weston (after a 30-day cure time) master carpenter Norm Abram finds the countertops being installed in the kitchen. Plumbing and heating expert Richard Trethewey shows Kevin how the house is being cooled, with an a la carte, split-type air conditioning system featuring outdoor heat pump units and indoor wall mounted units. These provide zoning control in the different areas of the house. Upstairs in the master bedroom, Kevin finds Amy and designer Carole Freehauf putting down eco-friendly carpet tiles that are easy for DIY-ers to install.

Master carpenter Norm Abram meets with Michelle Moore from the U.S. Green Building Council to learn more about their LEED for Homes program and how the Weston house will qualify. Landscape contractor Roger Cook installs porous pavers in the driveway, while the Port Orford cedar pergola is being craned into place on the front lawn. Bensonwood woodworker Kevin Bittenbender shows host Kevin O'Connor how they build window trim kits in the Bensonwood shop and later how they are installed in the field at the project house. General contractor Tom Silva shows Norm the new industrial steel staircase going in and how the look is softened by reclaimed Douglas fir stair treads. In Nantucket, Massachusetts, Norm and designer Carole Freehauf visit remote Esther's Island to see how one developer has achieved luxury living completely off the grid.

The Favat family takes host Kevin O'Connor to see Land's Sake Farm, a local non-profit farm stand where they can get organic flowers, fruits, vegetables, and even timbers for their house. Back at the project house, landscape contractor Roger Cook sets the last of several underground tanks that are part of the rainwater harvesting and runoff control system required by the town. On the back entry porch, general contractor Tom Silva uses a new hidden deck-fastening system to put down composite decking. Upstairs, Tom's brother Dick Silva is cladding a wall in reclaimed galvanized metal to achieve a rustic and industrial feel. Conservation commissioner Brian Donahue shows Kevin how the town of Weston is partnering with Land's Sake Farm to sustainably harvest trees from the town forest for use by its residents.

At the project house in Weston, landscape contractor Roger Cook installs granite steps on the entry porch, precast footings for the pergola, and Goshen stone for the front patio. General contractor Tom Silva installs the rough sawn and reclaimed white oak flooring on the first floor. Host Kevin O'Connor takes homeowner Amy Favat to a local appliance showroom so she can "test drive" new kitchen appliances before buying them. Security systems specialist Greg Smizer installs a cure for the cell phone "dead zone". It's a cell phone zone extender system that works by capturing the cell signal outside and amplifying it inside the home. Kevin invites designer Carole Freehauf to the house to offer a few sophisticated and unexpected options for furnishing a timberframe home.

At the project house in Weston, host Kevin O'Connor finds solar energy specialist Jeff Wolfe installing eighteen solar panels that can provide up to 75 percent of the home's power needs. Later, in Alstead, New Hampshire, builder Tedd Benson shows Kevin a modest prefabricated Habitat for Humanity house that a group of 450 volunteers assembled in 8 days. Back in Weston, general contractor Tom Silva installs the red distressed vertical boards that will adorn the walls of the second floor hall. At the Bensonwood shop, master carpenter Norm Abram meets timberframer CJ Brehio to see how he is laying out and carving "2008" in Roman numerals into a reclaimed Douglas fir timber for the first floor. Back at the project house, Tom shows Kevin the new custom half-round copper gutters and decorative brackets going in on the street side of the house.

On the roof at the project house in Weston, plumbing and heating expert Richard Trethewey shows host Kevin O'Connor the new solar hot water system that makes use of evacuated tube technology—the perfect solution for a cold climate. General contractor Tom Silva gives homeowner Amy Favat a progress tour of the house. The rough plumbing and electrical are nearly complete, the cabinets are in, and the concrete countertop fabricators are on site to template for the tops, which will take four to six weeks to make and to cure. At the Bensonwood shop in New Hampshire, Tom lends a hand to finish carpenter Dennis Wright as he installs "home slicker" and pre-stained white cedar shingles to the exterior wall panels. Back in Weston, plumbing contractor Lynne Keating shows Richard how the plumbing connections are made on the prefab floor panels.

Host Kevin O'Connor arrives in Weston and finds a busload of masons just in from Wisconsin to help with the exterior stone veneer, while general contractor Tom Silva shows homeowner Amy Favat the new synthetic slate roofing material made from 80 percent recycled content. On the outside of the building, Jason Buechel and his crew install a New England fieldstone natural stone veneer that goes up with dark grout and deeply raked joints to give it a dry-laid look. Meanwhile, in Brookline, New Hampshire, master carpenter Norm Abram meets third generation lumber and paneling expert Tom Bingham to see how he is making custom wainscoting, chair rail, and horizontal wallboards for the Weston home. Back in Weston, Tom shows homeowner Pete Favat the new custom garage doors and how they are installed and operated.

Three weeks into the new house raising in Weston, Massachusetts, and the building envelope is almost complete. The Bensonwood crew places the last of the roof panels and sets the five-thousand pound cupola to cap off the house. The roof panels are made in the Bensonwood workshop from over fifty different structural insulated panels while crews work to apply shingles and a standing seam copper roof to the cupola before it flies. An important part of the energy efficient story with the Weston project is the new windows. General contractor Tom Silva shows host Kevin O'Connor how the windows are properly flashed and installed in the Bensonwood workshop in New Hampshire.

Two weeks into the new house raising, master carpenter Norm Abram meets architect Chris Adams for a tour of the first and second floors. At the Bensonwood shop in Walpole, New Hampshire, plumbing and heating expert Richard Trethewey meets plumbing contractor Lynne Keating to see how she is running PEX water supply lines and ABS drainage pipe to the back-to-back kids bathrooms, both of which are assembled in the shop as one pre-built "module". Back in Weston, to keep pace with the fast building schedule, landscape contractor Roger Cook is already working on building the landscape plan. It calls for an elaborate drainage plan with a rain garden on the tail end to help protect the wetlands from surface runoff and contaminants. Homeowner Pete Favat and his daughter Juliette lend a hand building the rain garden and planting it with native plants and seeds.

The second week of the house raising begins with a ceremonial timberframe raise on the first floor—by hand. The rest of the job will be done with a crane including lifting a forty-eight foot long assembly of Douglas Fir timbers and live Oak crucks that will run the length of the entire first floor. Timberframe captain Mark Roentsch shows host Kevin O'Connor how the assemblies are joined together and flow into place. Homeowner Pete Favat shows Kevin the new kitchen space, while master carpenter Norm Abram travels to Claremont, New Hampshire, to see the custom kitchen being fabricated and finished using hand-applied milk paint and distressing techniques used to make the new cabinets look at home in an "old" barn. Back in Weston the first floor exterior walls featuring windows and some finishes already installed are craned into place.

Homeowners Amy and Pete Favat are on site in Weston for the first day of "raising" their new house but the excitement is soon tampered by unexpected rain. After a two-day rain delay, the Bensonwood crew begins by craning in and setting the mechanical room module and all of the walls for the basement level. In the New Hampshire workshop, plumbing and heating expert Richard Trethewey and mechanical systems manager Paul Boa fabricate the floor panels and add radiant heating and insulation in the comfort of a controlled environment. Back on site in Weston, the completed floor systems are craned into place. Despite continued rain, the crew manages to close in the basement level, and Amy gives host Kevin O'Connor a tour of the amenities on that floor—parking for two cars, a mudroom, workshop, powder room, kitchenette, and media room.

With 75 percent of the new prefabricated house being built in a workshop, host Kevin O'Connor opens the show at Bensonwood in New Hampshire, where today it's all hands on deck. General contractor Tom Silva meets up with builder Tedd Benson to see how his crew prefabricates interior and exterior wall systems, while next door in the timberframe shop, job captain Mark Roentsch shows master carpenter Norm Abram the assembly of salvaged Douglas fir and live oak timbers that will frame the dining area. Master electrician Allen Gallant works inside with the Bensonwood crew to pre-wire the building with a new plug and play wiring system, while security system contractor Greg Smizer preinstalls chases and wiring for alarm and data cables. Once in Weston, work on site will be a matter of connecting the wires and getting inspections.

Host Kevin O'Connor arrives in Weston to find homeowners Amy & Pete Favat in the backyard, cutting back the spring overgrowth so the workers can get through. General contractor Tom Silva begins building the new house by setting the pre-cast foundation walls that are poured in a factory then trucked to the site and lifted in by crane. In New Hampshire at Bensonwood, builder Tedd Benson shows Kevin the work in the timberframe office, and demonstrates how his crew is using sophisticated software and computer-controlled cutting machines to begin fabricating over 300 timbers for the project. Back in Weston, the next step is to pour the slab for the basement and garage floor, so plumbing and heating expert Richard Trethewey installs a new insulated in-slab radiant heating system. Landscape architect Wes Wirth presents a plan for the new yard that helps deal with the wetland setbacks, excessive road noise, challenging topography, and existing garden beds.

Host Kevin O'Connor drives up to find the old house gone, and general contractor Tom Silva finishing the job by demolishing the chimney and foundation with an excavator. The old concrete and brick will be crushed, trucked away, and used as base material for new roads, while the rest of the house will eventually find new life as affordable housing, but for now it's being stored at the ReStore in Springfield, Massachusetts. John Grossman shows Kevin how the non-profit center operates, and how much salvaged material came out of our house. Up at the shop in Walpole, New Hampshire, Kevin meets architect Chris Adams and homeowner Amy Favat to see how she planned her family's dream home, and to take a tour of the new house—via a 3-D software program that allows them to design and "build" the house virtually.

For the new season, host Kevin O'Connor and master carpenter Norm Abram reveal that This Old House will be building new—a prefab, eco-friendly home that will feel like an old barn. Homeowners Amy & Pete Favat love their land, but have outgrown their 1970s-era home, so they'll deconstruct the old house to make way for a new one that will better suit their active family. To achieve their vision of a vacation home "all year round", custom homebuilder Tedd Benson and his staff are designing and prefabricating the new state-of-the-art timberframe home, with general contractor Tom Silva pulling it all together on site. To see how Tedd's panelized system looks in the field, Norm and Tedd visit a recent project in Center Harbor, New Hampshire, while back in Weston, Tom works with deconstruction contractor John Grossman to take the old house apart by hand, in a way that saves landfill space, and allows the reuse of building materials.

Free Trial Channels

Seasons